Acetators and Pasteurizers

PROCESS YOUR FRUITS

WITH GILSON

PASTEURIZATION MATERIALS – PASTEURIZERS

TRANSFORM YOUR FRUITS WITH EQUIPMENT

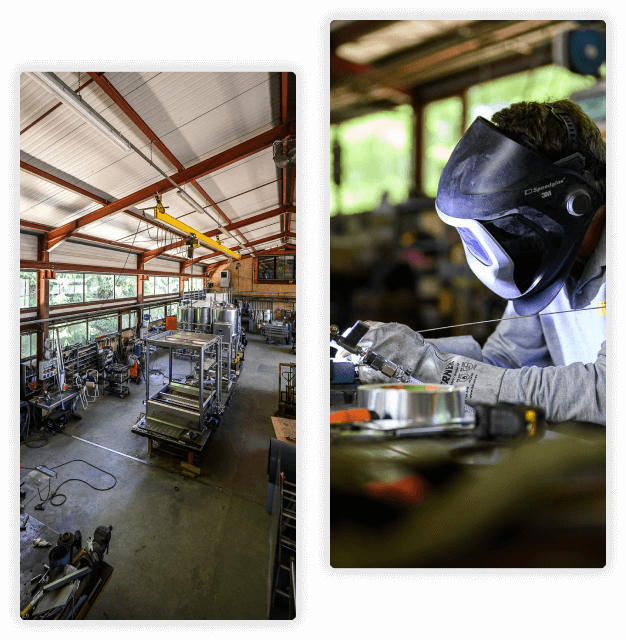

Founded in 1959, the GILSON company has

to its credit more than 400 installations of pasteurizers and acetators in France and

around the world.

Gilson manufactures equipment for the pasteurization of simple or sparkling fruit juices, nectars, your coulis, purees, jams, beers, vinegar or milk and its derivatives.

From extraction to bottling, we provide you with a whole range of machines that are part of the transformation process of your fruits and vegetables. We work on artisanal and family type chains or semi-industrial.

GILSON PASTEURIZERS AND ACETATORS

Gilson equipment is known for being reliable, adaptable, robust, versatile and efficient, easy to maintain, integrating manual, semi-automatic or automatic operations.

Pasteurizers

Design and production of pasteurization equipment for home-made and semi-industrial production.

Acetators

Manufacturer of acetators for

the transformation of your fruit juices or beers into vinegar.

Complete lines

The study and design of complete, personalized and adapted installations

to your needs.

Other equipment

We offer you all the necessary equipment for a transformation workshop: pack press, grater, refiner, bleaching belt, capper, bag in box filler, pumps, labelling machines, storage or mixing tanks, etc…

We listen to the needs of the producer and we constantly update our material.

Gilson positions itself as a true partner of the fruit grower

OUR NEW LOW ENERGY PASTEURIZER

ErgoPast

New in 2021

Here is our new pasteurizer: The ERGOPAST! Its design increases heat conversion performance and significantly reduces energy consumption. Ergopast reduces energy requirements by 30%.

Our jobs

PASTEURIZATION OF FRUIT JUICES, compotes, purées, nectars.

Discovered and systematized by Louis Pasteur, the pasteurization is a technique of conservation of food by which those are heated at a temperature and a definite duration.

This system significantly reduces bacteria and other pathogenic micro-organisms, while maintaining the quality of the product in terms of vitamins, color and taste. Each product does not answer the same criteria of pasteurization.

The objective is to make the product fit for consumption and to extend its shelf life.

As each customer has specific needs, we adapt our equipment to your requirements: fruit juices, coulis, purees, beer, milk, etc.

GILSON offers several types of pasteurizers:

- Tubular and plate heat exchangers

- DITZLER type installation

- types of energy: electricity, gas, steam, oil, superheated hot water

ORGANIC REACTORS FOR THE MANUFACTURING OF WINEGROW

This is the most common method: 98% of vinegars produced today, including organic vinegars, are processed using this method.

Vinegar is produced from fermented juices such as clear, full-bodied, pulpy or fibrous juices or beer. The liquid circulates in an acetator where the action of bacteria (the acetobacters) will transform the alcohol into acetic acid, component of the vinegar.

Gilson supplies bioreactor acetators with production capacities ranging from 50 to 500 liters / 24h. Made of high quality stainless steel and equipped with proven technology.

Our machines are 100% scalable and can be adapted to meet your specifications.”